Access Control, Inspection, Luggage X-Ray Machines, X-Ray Scanners

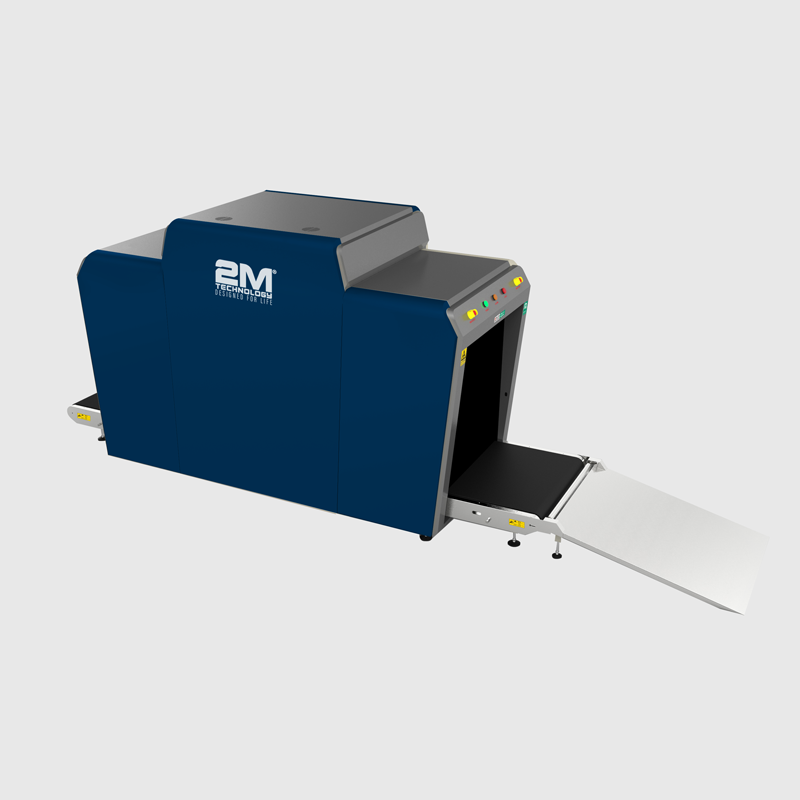

2MX-8065 X Ray Baggage and Parcel Inspection Scanner

- Tunnel Size 800 x 650 (mm)/ 31.5″ x 25.6″ (in.)

- Adjustable anode voltage 140-160kv

- 2x 17″ inch monitors

- Uninterruptible power supply (UPS) for computer

- Threat alert and material classification

Note: This is a special order item. Allow 4-6 weeks for delivery.

Product Documents

Downloads

| Weight | 1410.9 lbs |

|---|---|

| Dimensions | 112.1 × 43.1 × 60.5 in |

| Country of Origin | China |

| GENERAL | |

|---|---|

| Tunnel Size (LxW) | 800 mm x 650 mm / 31.5" x 25.6" (in) |

| Conveyor Speed | 0.22/0.72 ft/s |

| Conveyor Height | 341 mm / 13.4" (in) |

| Conveyor Max Load | 200 kg / 440.9 lbs |

| X-ray Dose Per Inspection | ≤4 µSv |

| Wire Resolution | dia. 0.102 mm copper wire (AWG38) |

| Spatial Resolution Level | dia.1.3 mm, Vertical: dia. 1.3 mm |

| Penetration | 28 mm steel guarantee, 30 mm steel typical |

| Penetration Resolution | dia. 0.202 mm copper wire (AWG32) under three-step aluminum wedge 9.5 mm, 15.9 mm, 22.2 mm |

| Spatial Resolution | Horizontal: dia. 1.3 mm, Vertical: dia. 1.3 mm |

| Noise | <60 dB |

| Film Safety | Guarantee ASA/ISO1600 Film |

| IMAGE SYSTEM | |

| X-Ray Sensor | L-Shaped photodiode array, 12 bit deep |

| Images Process | 24 bit real time processing, 4 colors analysis, Images displayed marked date and ID No., Count the number of bags |

| Image Display | High resolution of 1024 x 1280 pixel; Image Grey Level: 4096 |

| Image Enhancement | 1-64 times enlargement continuity, Color/BW, negative, high/ low penetration enhancement, brightening, darkening, gray level scan, super enhancement, elimination of organic/inorganic materials, local enhancement, pseudo color processing, edge enhancement, etc. |

| Image Recall | 30 images recallable |

| Explosives & Narcotics Detection | Suspicious organics highlight (atomic number Zeff=7,8,9) |

| Alarm | Alarm will sound with a box outline of the suspicious object(s) including hard to penetrate material, explosives and drugs |

| Threat Image Projection (TIP) | Insertion of fictional but realistic images of threatening items into baggage during screening operation for training purposes to assess image identification capabilities |

| Image Archive | Up to 50,000 images stored automatically, enable transferring to USB disk, and converting to JPG, BMP and other general formats |

| Miscellaneous Functions | Time/date display, counters, user management, system on/ X-ray on timers, power on self-test, built-in diagnostics, dual-directional scanning, system log, system standby and stimulation training, etc. |

| Network Applications (Optional) | Multiple remote applications available based on Ethernet LAN and windows platform, such as image centralized storage and identify, recheck workstation etc. |

| X-RAY GENERATOR: | |

| Anode Voltage | 140 KV - 160 KV adjustable |

| Ray Direction | Downward |

| Cooling/Duty Cycle | Oil Cooling / 100% |

| CONTROL SYSTEM | |

| Monitor | 2 x 17" (in) LCD monitors, 1280 x 1024, one console desk |

| RAM | 4 GB |

| Hard Disk | 2 TB |

| Keyboard | Special design |

| System | Windows 10 |

| Electric Roller | Three-phase |

| OPERATING ENVIRONMENT | |

| Operation Temperature/Humidity | 5 °C - 40 °C (41 °F - 104 °F) / 0% - 90% (non-condensing) |

| Storage Temperature/Humidity | -20 °C - 60 °C (-4 °F - 140 °F) / 10% - 90%(non-condensing) |

| Operation Power | 220 VAC (±10%) 50±3 Hz (Optional: 100 VAC, 110 VAC, 120 VAC, 200 VAC) |

| Power Consumption | 1.0 KW |

| UPS | Options: 15 mins, 30 mins, 60 mins, etc. |

| Dimensions (LxWxH) | 2848.5 mm x 1095 mm x 1536 mm / 112.1" x 43.1" x 60.5" (in) |

| Weight | 640 kg / 1410.9 lbs |

| Gross Weight | 800 kg / 1763.7 lbs |

| Packing Size | #1: 212 cm x 122 cm x 177 cm / 83.5" x 48" x 69.7" (in) #2: 122 cm x 90 cm x 141 cm / 48" x 35.4" x 55.5" (in) |

| COMPLIANCE | |

| Certifications | ISO19001; ISO14001; OHSMS18001; CE RoHS FDA FCC |