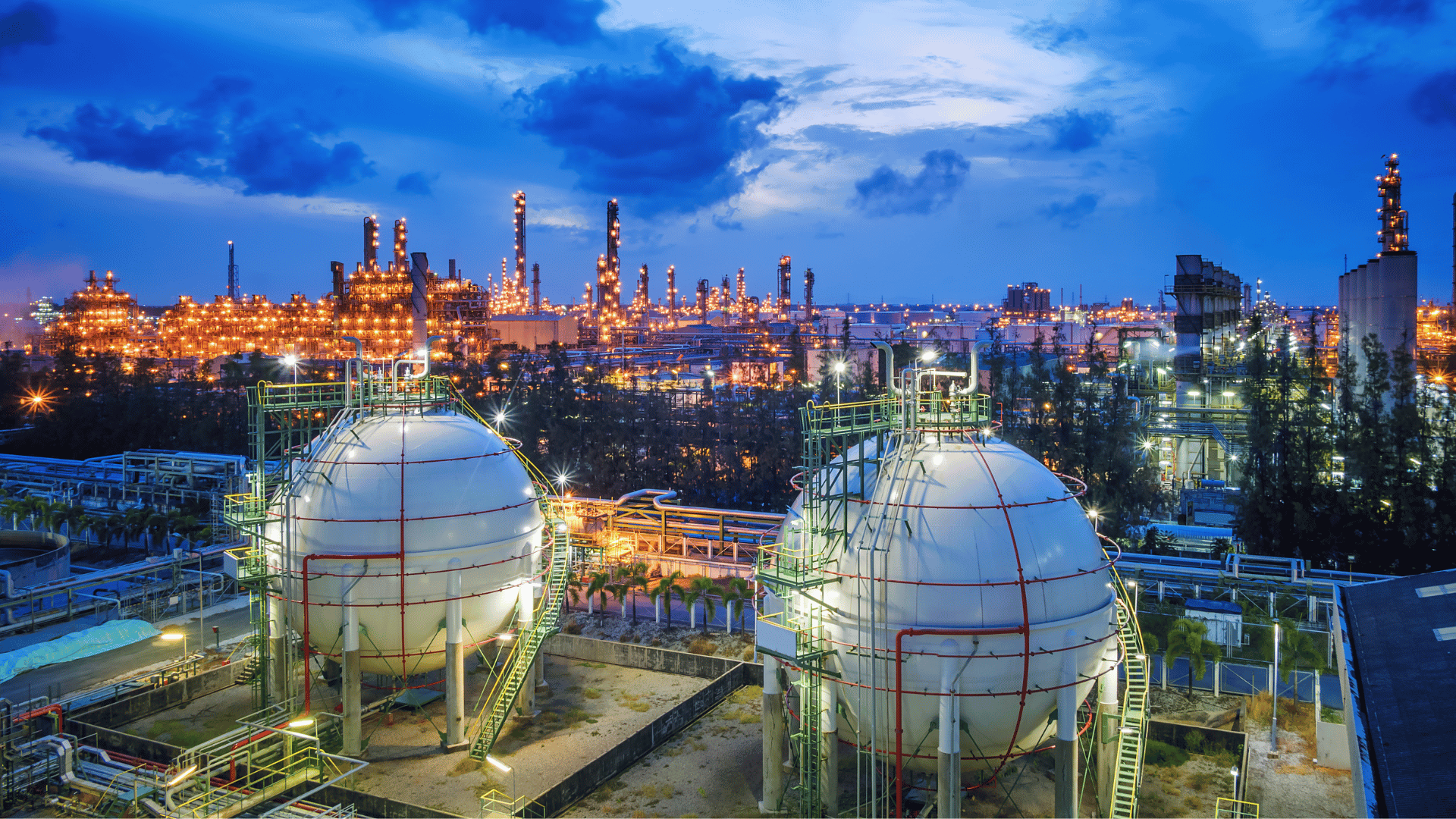

Hazardous areas are just like any other area and require close monitoring with security camera systems. However, the volatile nature of these places makes them susceptible to explosions so video surveillance must be done using specialized security equipment. In this article, we will go over the different components that comprise an explosion-proof security camera system and their functions.

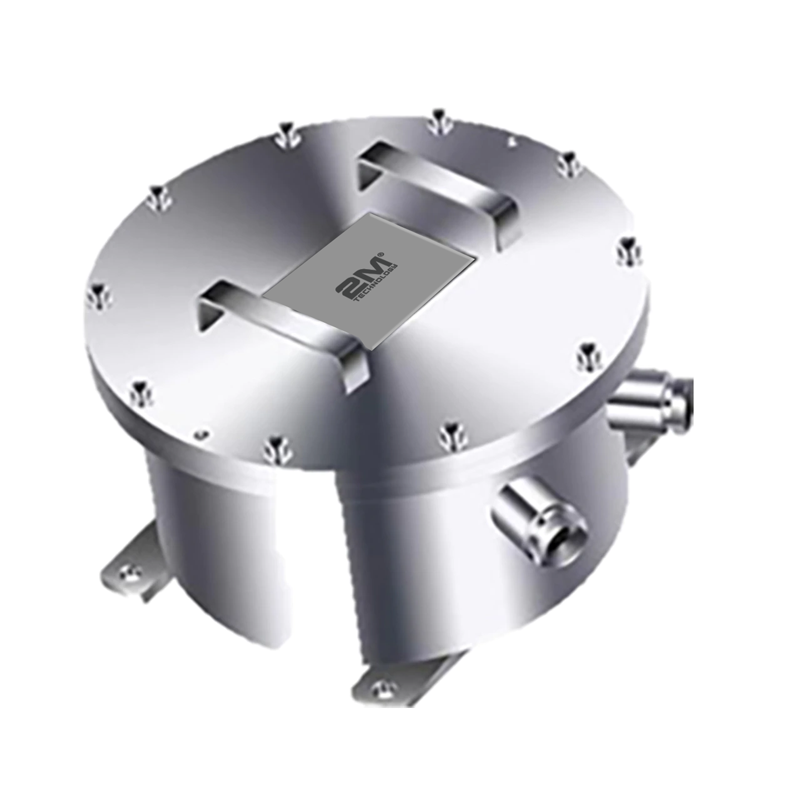

Explosion-Proof Housings

The specialized enclosure or housing surrounding a security camera is what makes the camera explosion-proof. Although the name can be misleading, explosion-proof housings are not designed to withstand explosions but rather to prevent them from happening. There are two different ways to achieve this. Some explosion-proof enclosures trap any sparks that the camera might emit to prevent them from igniting the surrounding atmosphere. Other housings contain pressurized inert gases that stop explosive gases from entering the enclosure and igniting any emitted sparks. Both methods are effective for preventing explosions and protecting workers in hazardous areas.

Protective Lens Accessories

Extreme temperatures or atmospheric pressure can cause the glass on camera lenses to crack which negatively affects the image quality. Explosion-proof enclosures cover the lens area with tempered glass to provide high-quality recording without breakage. Wipers are another essential feature for explosion-proof security cameras. These work similarly to the windshield wipers on your car and wipe away any condensation or smudges that may build up on the lens. Some housings may even come with sunshades to guard the camera lens from sun exposure and rain.

Explosion-Proof Mounts

Mounting security cameras provides the best view but explosion-proof cameras can be safety hazards if they’re not properly secured in place. Explosion-proof camera mounts are made of highly durable steel capable of supporting the weight of very heavy security equipment. Additionally, the steel’s resistance to corrosion ensures that the mount doesn’t break down and cause the camera to fall from position.

Explosion-Proof Wiring

All electrical connections to the security camera must also be explosion-proof and capable of withstanding extreme conditions. Explosion-proof conduits protect electrical wiring from heat, oil, and corrosion which degrade the performance of security cameras. Additionally, these tubes contain any sparks that could cause an explosion. Explosion-proof junction boxes act as a protective enclosure for the camera’s electrical connections, shielding them from the harsh environment of hazardous areas. And like explosion-proof housings, they prevent sparks from escaping and igniting the surrounding atmosphere.

Internal Temperature Regulator

Security cameras function the best when they’re in the right conditions. However, the conditions in hazardous areas are often very harsh with extreme temperatures. Explosion-proof security cameras should have a method for regulating their internal temperature, like a heater or cooler. A built-in heater prevents the camera from freezing in extremely low temperatures which degrades performance. An air or water cooler prevents the camera from overheating in extremely high temperatures which could spark an explosion.

Contact 2M Technology for Explosion-Proof Security Camera Systems

Securing hazardous areas requires careful planning and the right explosion-proof equipment to ensure the safety of all the people working in these areas. If you need explosion-proof security equipment for your business, the 2M Technology sales team can help you find what you need. In addition to offering explosion-proof cameras and accessories, we can custom design an explosion-proof camera housing for any type of security camera you have in mind. For more information, please call us at +1 (214) 988-4302 or send us an email at sales@2mtechnology.net!