Recently, a client approached us with a request for a custom explosion-proof camera housing that would allow them to safely use their Photron FASTCAM NOVA S16 camera in a hazardous location, specifically a facility that develops technologies for spaceflight.

Customer Background

The client is a leading innovator in the spaceflight industry, dedicated to making human space travel more accessible. Their efforts center on designing, testing, and producing technologies for future commercial space exploration. Given the high-stakes nature of space missions, it is crucial that these technologies undergo rigorous testing and development to ensure they are not only operational but also safe before being deployed.

The testing phase demonstrates how their designs might perform under the extreme conditions of space. Precise data collection during these tests is vital, as it helps researchers to conduct thorough post-event analyses and identify areas for improvement. High-speed cameras are integral to this process, allowing researchers to capture critical moments without putting themselves in direct danger should anything go wrong.

Challenges

High Risk of Explosions

The Photron FASTCAM NOVA S16 camera, which boasts an impressive video capture rate of 16,000 frames per second (fps), was selected by the customer for their operations. However, the camera was intended for use in a hazardous area where fuel would be present. Any sparks or heat emitted by the camera could ignite the flammable gases produced by the fuel, potentially triggering explosions. Additionally, the camera could be exposed to high temperatures that might cause damage. To address these issues, the client needed a solution that would not only protect the camera from damage but also prevent it from becoming an ignition source for explosions.

Limited Explosion-Proof Alternatives

While off-the-shelf explosion-proof camera systems are available, they lack the high-speed imaging capabilities the client needs. Since switching to a different camera that comes with a pre-made explosion-proof housing was not a viable option, the client turned to us for a solution. Our task was to create a custom explosion-proof camera housing that would fit around the Photron FASTCAM NOVA S16 camera, making it safe for use in their hazardous location while preserving its exceptional features.

Why 2M Technology?

The client chose 2M Technology because of our proven track record in providing specialized security solutions across various industries and environments. Having worked with them on a previous project, they knew they could rely on us to deliver another solution that would meet all their needs.

Our expertise in producing explosion-proof cameras and custom housings, along with our ability to accommodate special feature requests, made us the perfect fit for this project. Moreover, our extensive knowledge of UL, ATEX, and IECEx standards ensures that their custom explosion-proof camera housing is designed in full compliance with the strictest safety and regulatory requirements.

Solutions

When we were initially contacted for this project, the customer had a clear vision of the housing they needed, including technical specifications and safety mechanisms. However, they sought our help to design it and bring their idea to life.

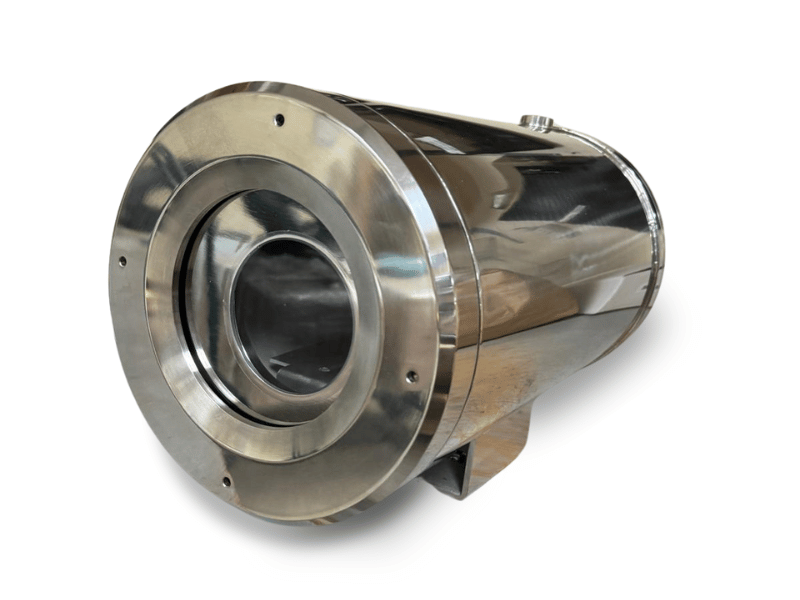

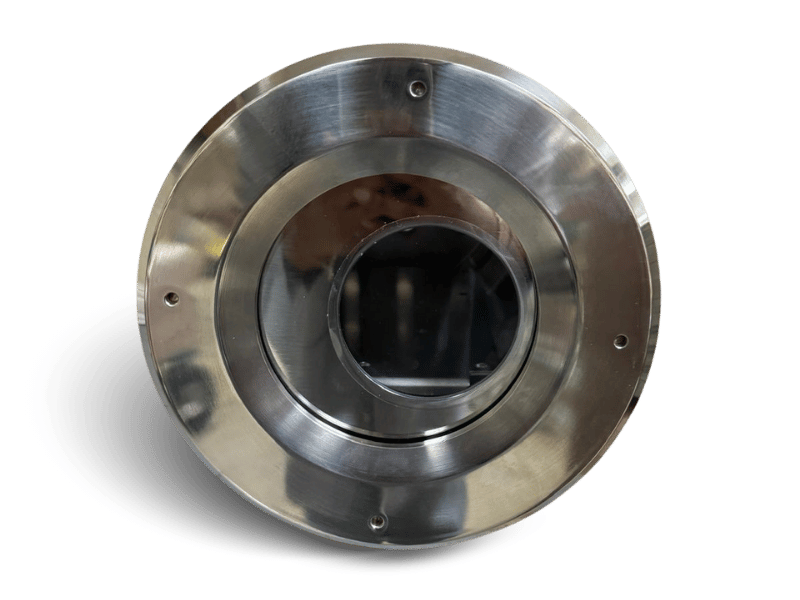

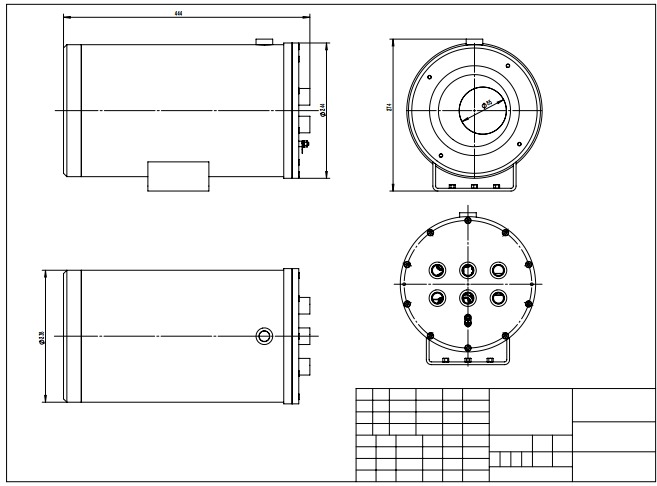

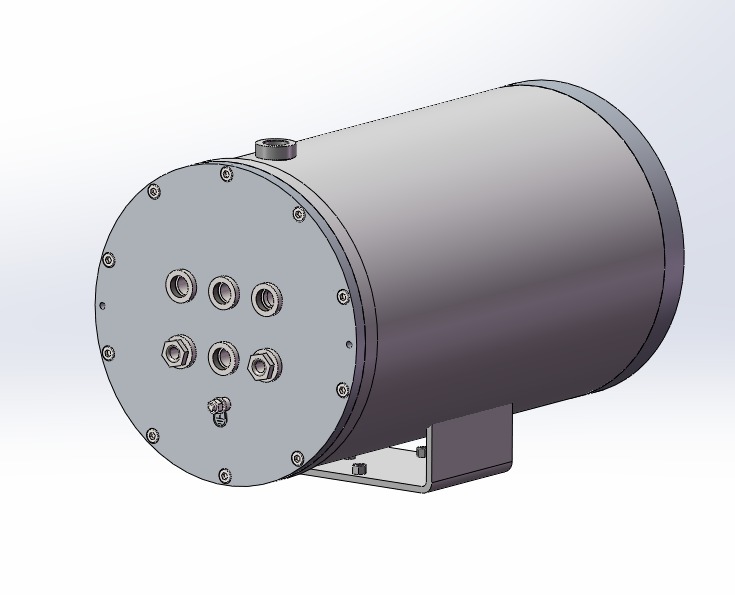

Custom Explosion-Proof Camera Housing

The primary requirement for the enclosure was that it be rated for Class I, Division 1 hazardous areas, ensuring the camera could safely operate in environments where explosive gases might be present. The custom explosion-proof camera housing features a tight seal that prevents any sparks or heat from exiting and igniting external elements. Constructed from 304 stainless steel, it is durable enough to withstand extreme conditions and contain any internal explosions.

Pressure-Relieving Muffler

Additionally, the client requested we include a muffler to manage changes in internal pressure and release excess pressure in a controlled manner. This was a concern because the camera could come into contact with extreme heat or overheat during operation, causing the internal pressure to rise. If this pressure became too high, there was a risk of the enclosure rupturing. The pressure-relieving muffler we incorporated safely vents any built-up pressure inside the enclosure without letting flames or sparks to escape, which could otherwise ignite an explosion if exposed to flammable substances.

Air Vortex Cooler

They also asked for a vortex cooler to regulate the camera’s internal temperature, as it could melt if exposed to high external temperatures. This cooler would also prevent overheating, since high-speed cameras like the Photron camera require substantial processing power, which generates heat during operation. The vortex cooling system we integrated into the housing circulates cool air to lower the internal temperature, preventing the camera from overheating due to its operation and exposure to external high heat.

Results

2M Technology delivered a fully customized explosion-proof housing that met the customer’s exact specifications, allowing them to safely use the high-speed imaging capabilities of the Photron FASTCAM NOVA S16 camera in their hazardous environment. The custom explosion-proof camera housing was designed to fit the dimensions of their camera and included the requested additions of a muffler and air vortex cooler. Despite the complexity of the design and the stringent safety standards we needed to meet, the project was completed within 6 weeks, demonstrating our ability to provide effective security solutions tailored for demanding industries within tight timeframes.

Ready to start on your security solution? Contact 2M Technology today for a free project estimate or consultation at sales@2mtechnology.net or at +1 (214) 988-4302!