In hazardous areas with flammable gases, vapors, or dust, safety is a top priority. Explosion-proof lights are essential in these environments to reduce the risk of fires or explosions. These lights provide reliable, long-lasting illumination in some of the most hazardous workspaces. Let’s take a look at why explosion-proof lighting is so important and how it helps protect both workers and equipment.

Why Do We Need Explosion-Proof Lighting?

Any worksite needs bright lighting to help workers see clearly and avoid accidents. But in certain industries, standard lighting can be dangerous. Hazardous areas, places where flammable gases, combustible dust, or ignitable fibers are present, require specialized lighting to prevent accidents.

If a regular light sparks, overheats, or malfunctions, it could ignite these materials and cause a fire or explosion. Explosion-proof lights prevent this by containing internal sparks or flames. They stop ignition sources from escaping and reaching the surrounding environment, which could have flammable hazards. This reduces explosion risks, keeping employees, equipment, and facilities safe and well-lit.

What are Explosion-Proof Lights and How Do They Work?

Explosion-proof lights are specifically made for use in hazardous areas. Their primary function is to prevent internal sparks, heat, or flames from igniting flammable materials outside the fixture. If an internal failure happens, such as a short circuit or electrical spark, the fixture contains it. This ensures ignition sources don’t spread to the external environment and trigger an explosion.

Here’s how explosion-proof lights provide protection in hazardous zones:

- Durable Enclosures: Made from strong materials like stainless steel, the thick casing can withstand internal explosions without rupturing.

- Flame Paths: Small gaps in the fixture’s joints cool down hot gases as they escape. By the time gases exit, they are no longer hot enough to ignite the surrounding atmosphere.

- Sealed Components: Electrical parts like wiring and switches are tightly sealed to stop sparks from escaping and to block flammable particles from entering.

- Heat Management: Equipped with cooling fins or heat dissipation systems, these lights prevent overheating that could otherwise lead to ignition.

An added advantage of explosion-proof lights is their ability to endure harsh conditions. While standard lights can fail in extreme temperatures, high humidity, or corrosive environments, explosion-proof lights are built to last. Their stainless steel construction resists rust and corrosion, making them suitable for areas exposed to saltwater or chemicals. Their tightly sealed enclosures also protect internal components from moisture, dust, and temperature fluctuations, ensuring reliable performance in even the toughest industrial settings.

Who Uses Explosion-Proof Lights?

Explosion-proof lights are necessary in industries that operate in hazardous areas. These industries often deal with flammable materials that could be ignited by sparks or heat. Here are some industries that rely on explosion-proof lighting:

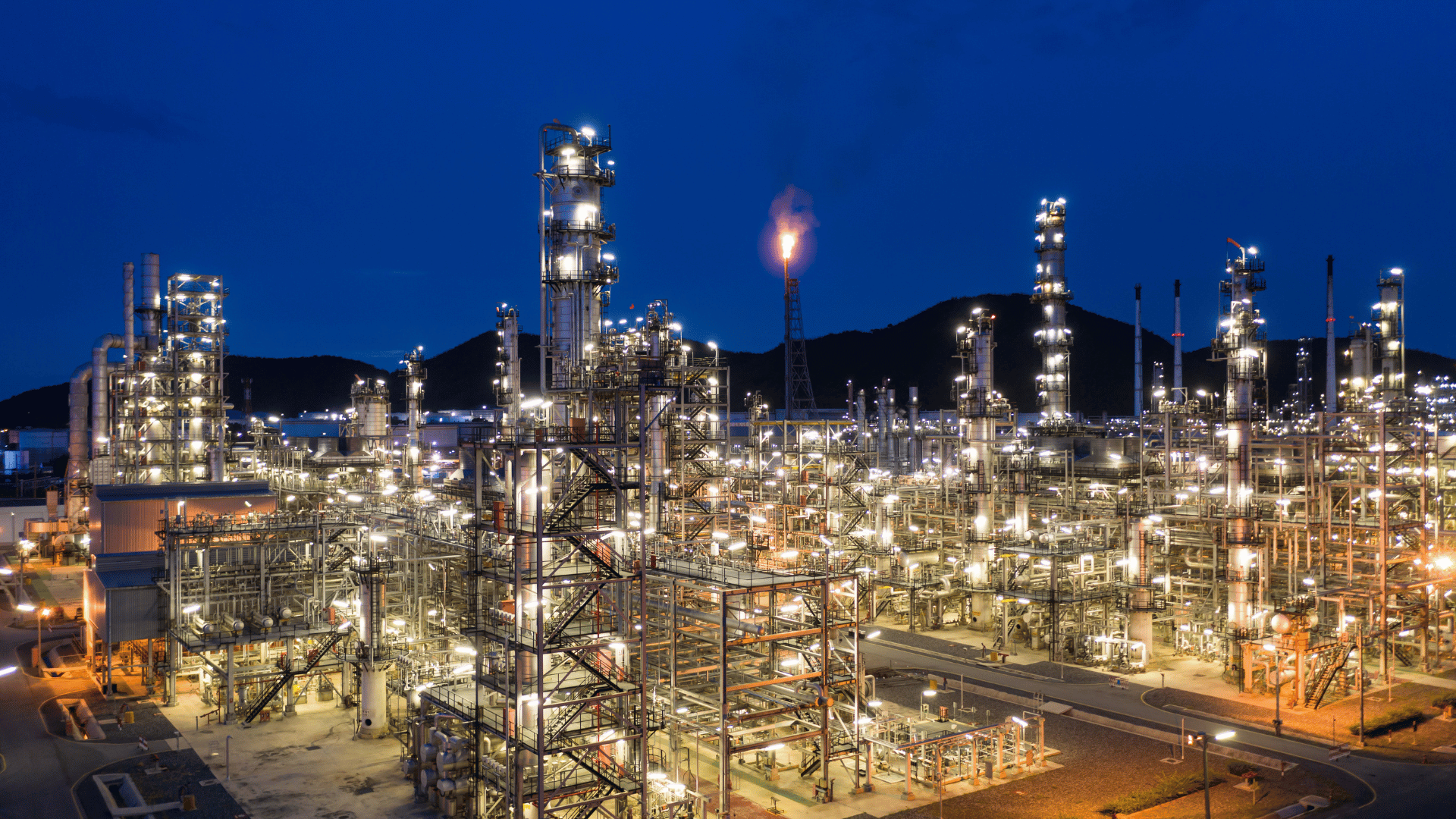

- Oil and Gas: Refineries, drilling sites, and fuel storage facilities, where flammable gases and vapors are common.

- Chemical Plants: Areas where chemicals are produced, processed, or handled, which can release volatile substances.

- Mining: Both underground and above-ground mines with explosive gases and dust.

- Manufacturing: Factories producing or using flammable materials such as paints, solvents, or chemicals.

- Waste Management: Facilities like landfills or sewage treatment plants that handle waste, which emits methane gas.

What are the Different Types of Explosion-Proof Lighting?

There are several types of explosion-proof lights, each designed for specific purposes and applications in hazardous industries.

Hanging Lights

Hanging lights are suspended from ceilings and provide directional lighting in industrial environments. They are often used in workshops, chemical plants, and other facilities where focused lighting is needed to illuminate specific work areas.

High Bay Lights

High bay lights provide bright and powerful illumination for large spaces with high ceilings. These lights are typically used in warehouses, manufacturing floors, and aircraft hangars, ensuring that expansive areas are well-lit for optimal work conditions.

Linear Lights

Linear lights are long, narrow lights that provide consistent illumination over extended areas. They are typically used in tight spaces, such as tunnels, corridors, and hallways, where their slim design allows them to fit into narrow spaces while offering reliable lighting.

Street Lights

Street lights are used to illuminate roads, pathways, and access routes in industrial areas like refineries and petrochemical plants. They keep workers safe by allowing them to maintain visibility as they travel within the site during low-light conditions.

Floodlights

Floodlights provide uniform, wide-area lighting for large outdoor spaces, such as construction sites, mining areas, and industrial yards. They are ideal for illuminating extensive areas and ensuring that work can continue safely even after dark.

Spotlights

Spotlights are used to give focused and intense lighting for tasks requiring precision, such as inspections, detailed work, or highlighting specific areas in industrial settings. Their concentrated beam helps improve visibility in critical tasks.

Portable Lights

Portable lights are mobile and easy to transport, making them ideal for temporary use during repairs, maintenance, or emergencies. These lights can be quickly moved to different areas as needed to provide essential lighting when stationary lights are unavailable.

Emergency Lights

Emergency lights provide illumination during power outages or emergencies, ensuring that workers can safely exit. These lights are commonly found in factories, offshore platforms, and other critical industrial sites.

Emergency Exit Signs

Emergency exit signs are essential for guiding workers to exits during emergencies. They clearly mark exit pathways, helping workers evacuate quickly and safely.

Protect Your Site with Explosion-Proof Lighting

Explosion-proof lights are important for keeping people and equipment safe in risky environments. At 2M Technology, we provide top-notch explosion-proof lighting solutions designed for reliable performance in even the most challenging industrial settings. Whether you need lighting for security, emergencies, or general illumination, we have the right solution for you. Trust us to help protect your workforce, equipment, and facility. Contact us today at +1 (214) 988-4302 or sales@2mtechnology.net to learn more about how our explosion-proof lighting can make a difference.