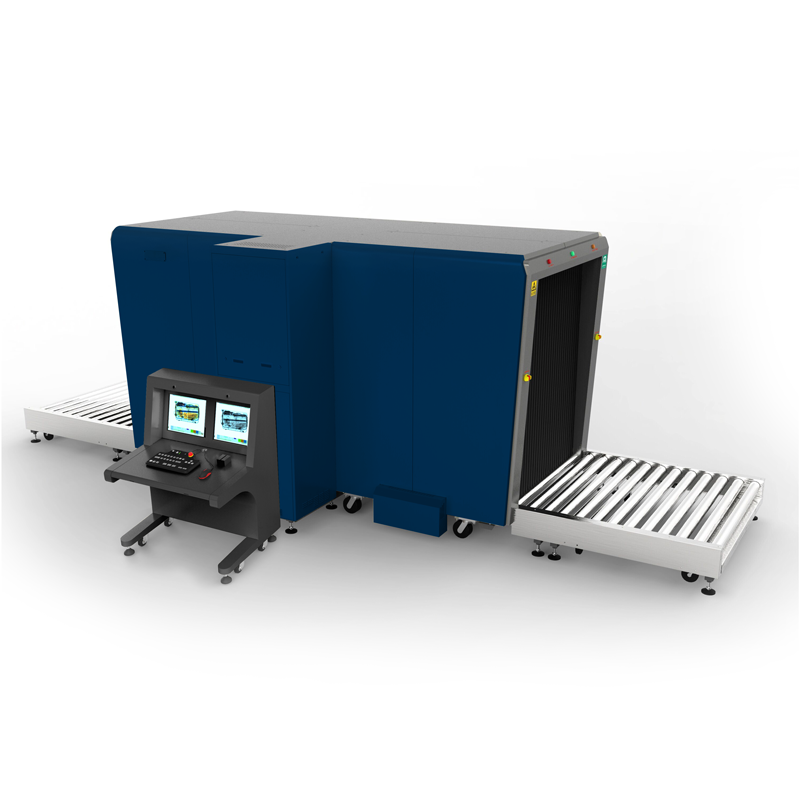

Global trade has exploded over the years, fueled by technological advancements that have made transporting consumer goods faster and easier than ever before. However, an unintended consequence of this progress was that it also made it easier for threats and contraband to travel the globe. The increased frequency and volume of cargo movement, coupled with the increased risk of threats, create new challenges for security and government agencies. Cargo and pallet X-ray scanners are essential for facilitating efficient trade while safeguarding against potential risks and criminal activities.

How Cargo & Pallet X-Ray Scanners Work

Cargo and pallet X-ray scanners work similarly to the X-ray machines you see in hospitals, but they are designed to scan much larger objects. Here’s a brief and very simple overview on how they work:

- X-Ray Generation: These scanners are equipped with a high-voltage generator that emits X-ray beams that can penetrate through various materials.

- X-Ray Detection: When X-rays pass through an object, the object absorbs some of their energy. Different materials with varying densities will absorb different levels of energy. Detectors on the opposite side of the machine measure the remaining energy of the X-rays.

- Imaging: The computer converts the data collected by the detector into an image that shows the density and composition of the scanned items. Dense materials like metals will appear darker, while less dense items like fabric or cardboard will be lighter.

- Visualization: The image is displayed on the monitor so inspection personnel can identify usual items or potential security threats.

Advantages of Cargo & Pallet X-Ray Scanners

Cargo and pallet X-ray scanners are invaluable for inspecting shipments as they enable agencies to restrict the spread of threatening items and enforce international trade regulations.

Efficiency

Performing manual inspections of shipments is extremely time-consuming and labor-intensive. They require a large workforce to meticulously search through every inch of a cargo container or pallet, leading to more errors and severe shipping delays. Cargo and pallet X-ray scanners streamline the inspection process and reduce workloads. In a matter of seconds, the X-ray scanner reveals the cargo’s contents without the need for a team to conduct a manual search.

Non-Intrusive Inspection

Unlike manual inspections, conducting inspections with cargo and pallet X-ray scanners does not require any physical contact with the shipment. The X-ray scanner generates a detailed image of the cargo’s contents, allowing teams to inspect the image instead of having to open individual boxes and packages. This not only reduces the inspection time, but also protects personnel from physical contact with potentially hazardous materials. Additionally, this minimizes the risk of damage to delicate or sensitive items.

Security

The primary purpose of cargo and pallet X-ray scanners is to detect prohibited or dangerous items, such as weapons, explosives, and narcotics. These items threaten public safety and national security as they often result in violence and fatalities. Identifying them early enables government agencies to seize the shipment and prevent their distribution.

Environmental Safety

In addition to protecting the people, cargo and pallet X-ray scanners are also important for protecting the environment. The importation of foreign plants, animals, and food products is heavily regulated in every country because these items can carry diseases that may potentially devastate delicate ecosystems. These X-ray scanners prevent this from happening by ensuring that each shipment only contains approved items.

Trade Enforcement

Besides providing protection, cargo and pallet X-ray scanners are useful for enforcing international trade regulations. Customs officials can use these scanners to verify that the contents of a cargo container match up with the import or export documents. Doing this reduces customs fraud and ensures that the correct tariffs and duties are paid on all inbound and outbound shipments.

Applications of Cargo & Pallet X-Ray Scanners

Cargo and pallet X-ray scanners are useful for any industry that transports large amounts of goods. This is just a few examples of where they’re used:

- Airports: Cargo and pallet X-ray scanners are most commonly found in airports to screen passenger luggage and air cargo. They help ensure the safety of passengers, aircraft, and environment by detecting prohibited items and potential threats.

- Seaports: A significant portion of the world’s goods travel via cargo ships. Seaports use cargo and pallet X-ray scanners to inspect shipping containers for security and customs purposes.

- Border Crossings: Customs and border protection agencies use cargo and pallet X-ray scanners at land border crossings to prevent the entry of dangerous weapons, drugs, and illegal migrants.

- Distribution Centers: Distribution centers use cargo and pallet X-ray scanners to ensure that the shipment has the correct items before being sent to the final destination.

Contact 2M Technology for Cargo & Pallet X-Ray Scanners

As global trade increases, so will the need for cargo and pallet X-ray scanners to ensure the safety and reliability of shipments. If you need a cargo and pallet X-ray scanner for your business, 2M Technology can help you find the right solution. We offer heavy duty X-ray scanners with adjustable density penetration capacity, advanced threat detection, and material classification. You can also customize the X-ray scanner to your specific needs and requirements. For more information, contact our sales team at +1 (214) 988-4302 or sales@2mtechnology.net!