In high-risk industries, there’s no room for mistakes when it comes to safety. Employees of these industries are exposed to extremely volatile conditions everyday but without their work, we wouldn’t have important resources that are needed to keep the world running. Explosion-proof security cameras offer security and protection to workers in hazardous areas, but without the added risk of causing an explosion.

What Is a Hazardous Area?

When most people hear the term “hazardous areas”, they usually think about places that involve gas or oil, but even flour mills and candy factories can be hazardous. The National Electrical Code (NEC) defines hazardous areas as locations “where fire or explosion hazards may exist due to flammable gases or vapors, flammable liquids, combustible dust, or ignitable fibers or flyings.” Since these areas are so volatile, strict regulations on electrical equipment are necessary to prevent devastating accidents. All electrical items used in hazardous areas must be IECEx (accepted globally) or ATEX (only EU countries) certified to ensure that their usage will not cause any explosions, including surveillance devices.

Hazardous Area Classifications, Divisions, & Groups

In the United States, hazardous areas are categorized into three classes, with each class being further organized into two divisions and various groups. Hazardous areas have to be classified using this system to identify what equipment can be used because each location has its own standards.

- Classes: The classes are based on the type of explosive or ignitable substances that may be present in that area.

- Divisions: The divisions are set according to the likelihood that a hazardous substance is present in an explosive or ignitable quantity.

- Groups: The groups are based on the physical properties of the hazardous substance and how easy it can be ignited.

| Class | Division | Group |

|---|---|---|

| I – Flammable vapor or gas may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where hazard is caused by frequent maintenance, repair work, or equipment failure. 2 – Ignitable concentrations of hazards are handled, processed, or used, but are normally confined within closed containers or closed systems from which they can only escape in cases of accidental rupture of these containers/systems or in cases of abnormal equipment operation. | A – acetylene B – hydrogen, butadiene, ethylene oxide, propylene oxide, acrolein C – ethylene, cyclopropane, ethyl ether D – acetone, ammonia, benzene, butane, ethanol, gasoline, hexane, methane, methanol, naphtha, natural gas, propane, toluene |

| II – Combustible dust may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where hazard is caused by frequent maintenance, repair work, or equipment failure. 2 – Ignitable concentrations of hazards are handled, processed, or used, but are normally confined within closed containers or closed systems from which they can only escape in cases of accidental rupture of these containers/systems or in cases of abnormal equipment operation. | E – combustible metal dusts such as aluminum, commercial alloys, magnesium F – combustible carbonaceous dusts such as carbon black, charcoal, coal, coke dusts G – other combustible dusts such as chemicals, flour, grain, plastic, wood |

| III – Ignitable fibers or flyings may be present | 1 – Ignitable concentrations of hazards exist under normal operation conditions and/or where hazard is caused by frequent maintenance, repair work, or equipment failure. 2 – Ignitable concentrations of hazards are handled, processed, or used, but are normally confined within closed containers or closed systems from which they can only escape in cases of accidental rupture of these containers/systems or in cases of abnormal equipment operation. |

In industries that deal with volatile substances, the risk of accidents and serious injuries stemming from explosions and fires are much higher so electrical equipment in hazardous areas are strictly regulated. Regular electronic items may produce heat or sparks that could ignite something in the atmosphere and cause an explosion so only certified electronics can be used in these areas. Since surveillance devices are electrical items, they are also subject to these regulations.

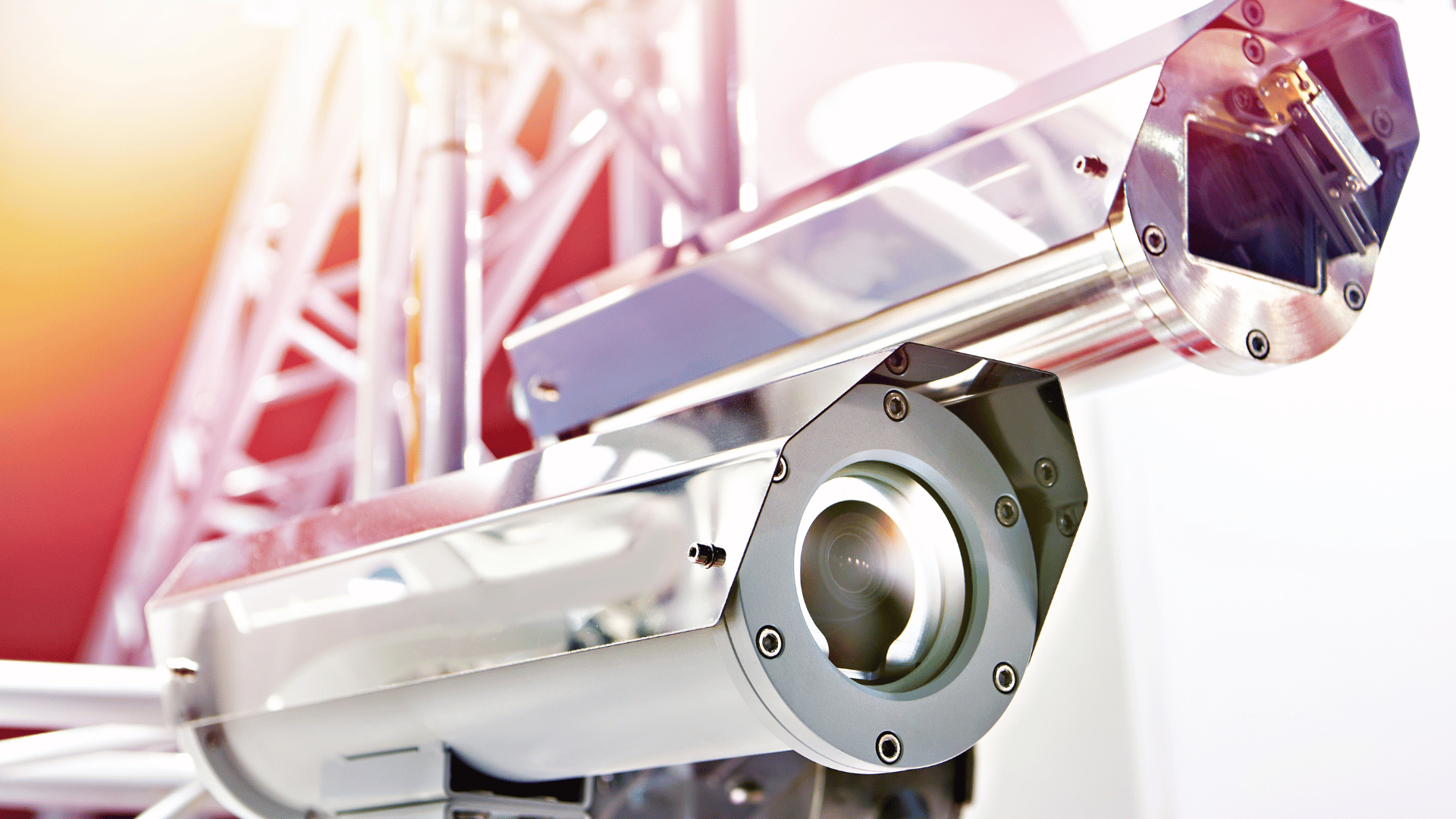

Explosion-Proof Security Cameras & Enclosures

In hazardous areas that require monitoring, explosion-proof security cameras are used. Explosion-proof cameras are security cameras that are protected by a specially-engineered housing or enclosure. Even though the name might suggest it, the purpose of explosion-proof cameras is not to withstand explosions, but to prevent them from happening.

There are two ways that explosion-proof cameras do this. In the first way, the enclosure is designed to contain any sparks or explosions that the camera may emit so that it doesn’t ignite the surrounding hazardous substances. In the second way, the housing contains pressurized inert gases to prevent explosive gases from entering the enclosure so that even if the camera does emit a spark, nothing will be ignited.

There is no right answer as to which method is better to use, but it’s important that explosion-proof security systems are used in every hazardous location to prevent accidents and protect workers.

All-Around Protection With Explosion-Proof Security Cameras

Security cameras are already used in just about any industry, but explosion-proof security cameras are especially necessary in hazardous areas because of the strict safety regulations and expensive machinery that are associated with these sites. Here are just a few reasons why explosion-proof cameras are needed.

Prevent Theft

Industries in hazardous areas typically use very specialized and expensive equipment in their production so installing explosion-proof security cameras can help deter theft. Additionally, some industries may deal with precious natural resources like oil or gas so constant surveillance is needed to ensure that these materials are not tampered with or stolen.

Ensure Compliance With Safety Protocols

Since hazardous areas carry a higher risk of injuries, there are stricter safety regulations and protocols that must be followed closely. Monitoring with explosion-proof cameras encourages workers and the facility to comply with safety rules and holds them accountable for careless mistakes.

Traceability

Many industries require the installation of security camera systems in order to provide traceability. Traceability refers to the ability to monitor and track the movement of parts/products as they go through the production or manufacturing process. Using explosion-proof security cameras is important because if anything is wrong with the product quality, the business will be able to review the recorded footage to pinpoint exactly why the issue happened and at what step of the process it occurred.

Secure Restricted Areas

In hazardous industries, there may be areas of the facility that are too dangerous to enter or that are restricted to personnel that have been authorized to work there. Installing explosion-proof cameras allow facilities to detect individuals in these restricted areas and take care of the situation.

Immediate Threat Detection & Response

A lot of hazardous industries deal with high-scale processing or production of essential materials such as oil, gas, aircrafts, plastics, and pharmaceuticals. The significant nature of these products make them targets of terrorism or even destruction from protesting environmentalists. 24/7 surveillance with explosion-proof cameras enable industries to detect these types of threats immediately so they can respond before anything happens.

Provide Evidence

Despite strict safety precautions being in place, accidents do happen in hazardous areas. Recording everything that happens with explosion-proof security cameras is useful because if an incident occurs, the footage can be reviewed and used as evidence for investigations or insurance claims.

Monitor Processes Remotely

Explosion-proof security cameras can even prevent injuries by allowing workers to oversee high-risk processes without physically exposing themselves to potential danger. With remote monitoring, employees would be able to keep a close eye on operations, but from a safe location distances away so that if an explosion does occur, they will be out of range.

Secure Hazardous Areas With Explosion-Proof Solutions From 2M

If you need explosion-proof surveillance equipment for a hazardous area, 2M Technology can help you. We offer IECEx certified explosion-proof security cameras, enclosures, and accessories that provide risk-free monitoring to high-risk locations. We can also design and manufacture a customized explosion-proof enclosure while ensuring that it complies with ATEX or UL requirements. For more information, contact our security experts by phone +1 (214) 988-4302 or email us at sales@2mtechnology.net.