Years ago, Costco was having issues with customers finding bones in their hot dogs, leading to “15 to 20 broken teeth a month” (NPR). But since they’ve been inspecting their products with X-ray scanners, that number dropped to zero. They’ve also implemented a new rule requiring all of their food suppliers to use X-ray inspection scanners to ensure that their products are free from foreign material contaminants. Meanwhile, Trader Joe’s has been hit with recall after recall and customers are starting to lose trust in the company. If Trader Joe’s wants to repair their reputation, they should follow Costco’s footsteps and start using food X-ray inspection scanners.

The Problem

Less than two weeks ago on August 17, Trader Joe’s announced a recall for one of their Multigrain Crackers with Sunflower and Flax Seeds due to possible metal contamination. This marks the fourth recall from Trader Joe’s in a month. Previously, they recalled two cookie products and frozen falafel for contamination with rocks and their broccoli cheddar soup for insect contamination. But what makes Trader Joe’s more prone to recalls than other food retailers?

Trader Joe’s bad luck with recalls can be attributed to their unique business model of outsourcing production to small-batch producers rather than using established large-scale producers. These smaller producers provide the company with specialty artisanal food products that their customers have come to love, but their facilities are more limited than large producers and they may not have sophisticated mechanisms in place to correct manufacturing errors. This results in foreign material contaminants unknowingly landing into packaged food products and being sold to customers.

The Solution

Even though Trader Joe’s has said that they source their products from facilities that are up to FDA standards, the FDA only inspects facilities once every 3 to 5 years. This means that the FDA is not able to catch the majority of food issues before they reach store shelves so they mostly depend on the manufacturer or consumer to notice any issues. However, having the customer notice the issue first can lead the public to believe that the company doesn’t prioritize food safety or the consumer’s health. To prevent this from happening, food manufacturers and distributors should utilize different methods to ensure food safety than what’s required by the FDA.

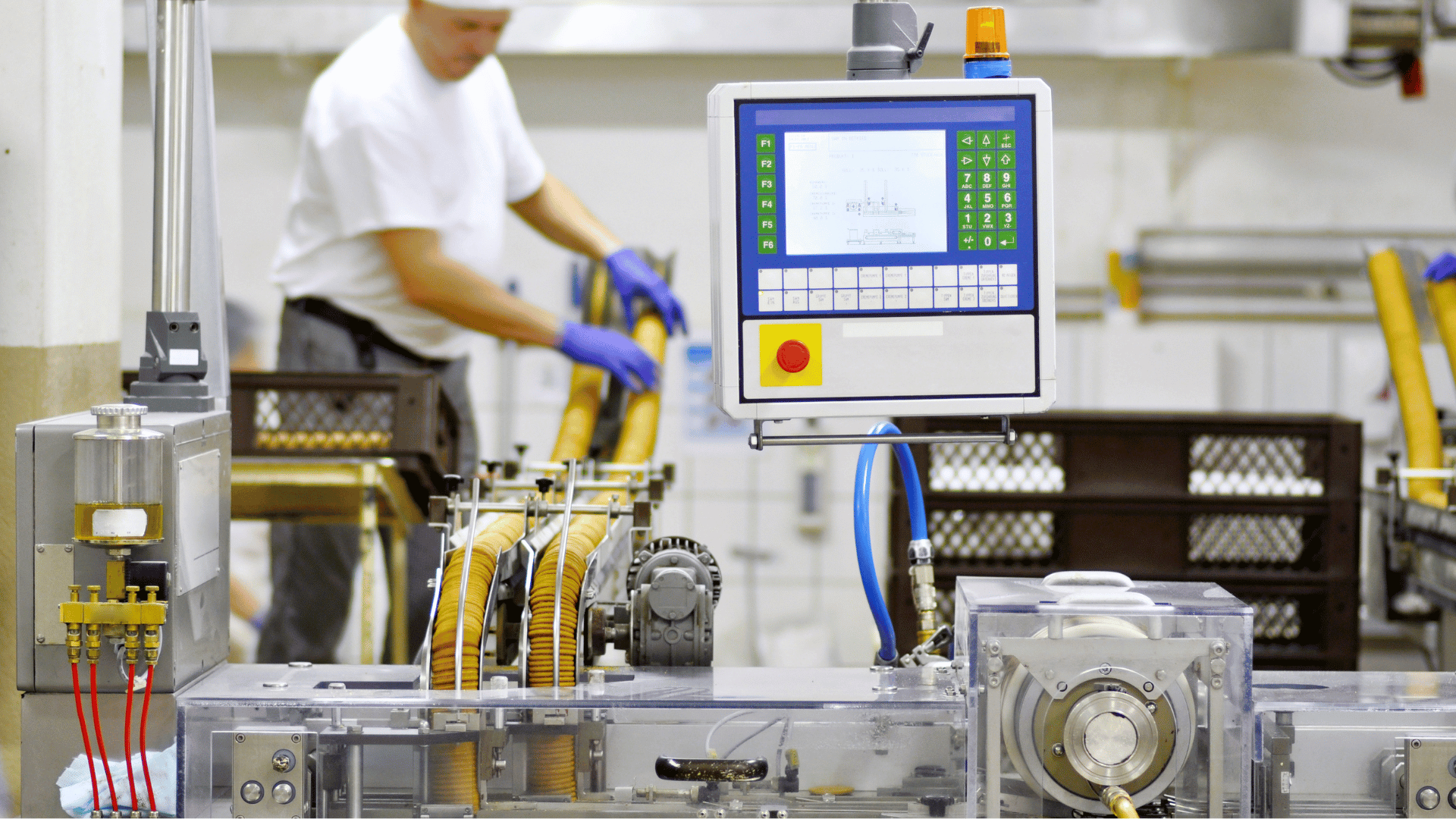

The best way to prevent contaminated food products from being sold to customers would be to inspect each item with food X-ray inspection scanners. These devices are much more effective than food metal detectors because they detect other foreign material contaminants such as bones, glass, plastic, rubber components, and wood. If any food product is found to be contaminated, the manufacturer can pull out the batch and stop it from being sent to stores. Not only that, identifying the contaminant would make it easier for them to trace it back to the source and remedy the issue so it doesn’t happen again. Food retailers can also benefit from using food X-ray inspection scanners to check their shipments before stocking the shelves.

Guarantee Food Safety With 2M Technology

In the long-run, food X-ray inspection scanners allow companies to maintain their profitability by preventing contaminated food from being sold to customers. In just seconds, the manufacturer can use advanced X-ray technology to identify any foreign material contaminants with more accuracy than manual inspection. Any manufacturer or distributor, not just Trader Joe’s, can benefit from using food X-ray inspection scanners because they reduce the amount of time spent performing quality checks, reduce the chance of lawsuits filed by customers, and reduce the risk of damages to their reputation.

If you’re a food manufacturer or retailer, don’t hesitate to contact 2M Technology today to learn about our food X-ray inspection scanners. We offer multiple models and sizes so you can get the best inspection solution for your facility. To get started with an estimate for receive more information, email us at sales@2mtechnology.net or call us +1 (214) 988-4302!